9 Air Clamp Manufacturers in 2024

This section provides an overview for air clamps as well as their applications and principles. Also, please take a look at the list of 9 air clamp manufacturers and their company rankings. Here are the top-ranked air clamp companies as of April, 2024: 1.Bimba Ltd, 2.GOOD HAND.

Table of Contents

Engaged in research on nitride semiconductor growth using the MBE method at Waseda University Graduate School. After graduating from graduate school in 2016, he joined a non-ferrous metal manufacturer.

Engaged in equipment maintenance and engineering work at metal smelting plants. Moved to a chemical manufacturer in 2022. Engaging in similar tasks.

What Is an Air Clamp?

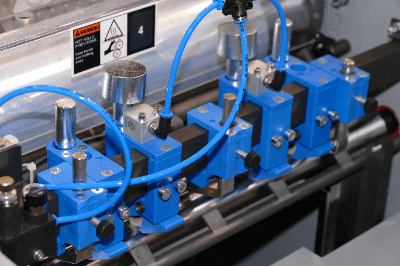

Air Clamps are clamps that operate using compressed air.

A clamp is a device that holds an object in place by pressing down on it. It is possible to press down with more force than manual operation. Widely used in factories, it is one of the indispensable tools for processing materials such as metal products and wood.

Since they do not use electricity, they reduce the risk of fire or electric shock at the work site. However, proper maintenance is required, and regular lubrication keeps the clamps running smoothly and extends their service life. It is also important to set the air pressure appropriately, as excessive air pressure can cause damage to clamps and work pieces.

Uses of Air Clamps

Air Clamps are widely used in factories. The following are the main applications of Air Clamps:

1. Metal Processing

Air clamps are used for cutting metal plates and pipes in metal processing. They are also indispensable tools in processes such as welding and bolting. Air Clamps are capable of high torque and force, allowing work to be performed with a high degree of precision.

2. Woodworking

Air clamps are used for cutting and drilling in woodworking. They are also used for gluing wood. They can hold wood firmly, which improves the accuracy of work.

3. Automobile Maintenance

In automotive maintenance, air clamps are used to replace or adjust engine parts and change tires. The high torque of Air Clamps firmly holds heavy automotive parts.

4. Painting

Air clamps are sometimes used to secure spray guns in painting applications. Spray guns secured by Air Clamps are less likely to shake, thus ensuring a uniform coating.

Principle of Air Clamp

Air Clamp is a type of toggle clamp that uses compressed air as its power source to hold an object in place. The source of compressed air is generally a device such as an air compressor. The compressed air is sent to the Air Clamp through an air line.

Inside the Air Clamp is a cylinder that opens and closes the clamp. The cylinder can close the clamp by pushing up the piston as compressed air flows in, and open the clamp when air is removed from the cylinder. The operation is generally controlled by a solenoid valve, which is operated by sending commands to the solenoid valve through button operation or a foot pedal.

A toggle mechanism is often used for the clamping part. The toggle mechanism is a type of link mechanism consisting of two links and a slider.

Types of Air Clamps

Air Clamps are widely used in various industries. The following are examples of Air Clamp types:

1. Integrated Air Clamp

Integrated Air Clamps are air clamps with the clamp and cylinder integrated into one unit. They feature a compact design and can be used in any installation location. Another advantage is that they are easy to install.

2. Parallel Gripper

This clamp is made of multiple arms. The arms move in parallel with each other to firmly grip an object. This type of clamp is particularly effective when handling large items.

3. Rotary Clamp

This clamp can process an object while rotating it. Since the clamp can be rotated while holding the workpiece in place, work efficiency is greatly improved.

How to Select an Air Clamp

Air Clamps are useful tools that greatly improve work efficiency, but there are a few important points to keep in mind when selecting the right Air Clamp.

1. Intended Use

Select the appropriate size and force for your application. Larger Air Clamps with greater force are suitable for handling large parts, whereas smaller Air Clamps are better suited for handling smaller parts.

2. Shape

Various shapes are available, including straight and angled types, and mounting methods such as base mounting and flange mounting can be selected. It is important to select the appropriate shape and mounting method according to the work to be performed and the installation location.

3. Clamping Speed and Repeatability

Clamping speed and repeatability are also important factors that greatly affect work efficiency. A high clamping speed is required when performing a large number of operations in a short time. High repeatability is also important for precision work.

List of 9 Air Clamp Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- Germany

- Japan

-

-

-

-

-

Bimba Ltd

Single Acting Air Clamps

Manufacturer Overview

Bimba Ltd., first founded in 1957 and acquired by IMI plc in 2019, is a manufacturer of motion control components. The company's products include four main categories of actuators that include pneumatic, hydraulic, electric, vacuum, and other developing actuator technologies. In simple terms, the company's products are engineered devices that produce the force to make something move, including factory machinery and robots used for painting in automotive plants. The company also offers two types of customized services: one that includes the modification of its existing components and the other that includes full design, engineering, and production.

-

-

-

-

-

GOOD HAND

Pneumatic Vertical Toggle Clamps

Manufacturer Overview

GOOD HAND ENTERPRISE CO., LTD., established in 1974 in Taichung, Taiwan, is a manufacturer specializing in clamping tools and accessories. Its product line includes toggle clamps, C clamps, F clamps, gear pullers, and clamp accessories, in which this precision-engineered products find utility across metalworking, woodworking, and construction industries. It serve the critical function of securing workpieces during machining, assembly, or welding processes, ensuring accuracy and safety. The company has gained notoriety in numerous industrial sectors as a result of its adherence to producing quality clamps and accessories.

-

-

-

-

-

Bernd Siegmund GmbH

Pneumatic Clamps

Manufacturer Overview

Bernd Siegmund GmbH, founded in 1982 and headquartered in Bayern, Germany, is a manufacturer and supplier of modular welding and clamping tables. The company's product line is dedicated to a series of plasma nitride-hardened, precision modular welding tables with a hole grid building block system that is complemented with a range of compatible clamping tools that make it possible to actualize complicated and multiple welding jigs efficiently and accurately. Quantum Machinery Group is the official distributor in the United States, located in Charlotte, North Carolina.

-

-

-

-

-

KOSMEK LTD.

Machine Tool Related Products

Manufacturer Overview

Kosmek Ltd. is a manufacturer of production and automation products and systems that was established in 1986 in Tokyo, Japan. The company’s products include quick mold change systems, work clamping systems, and robotic automation systems. These are primarily used by clients in the metal or plastic fabrication, automation, and mechanical engineering sectors. The company also offers product customization, installation, and consultation services for customers with unique project specifications. Some of its notable clients include Panasonic, Mitsubishi, and Honda.

-

-

-

-

-

Pascal Corporation.

Hydraulic clamp / Air clamp

Manufacturer Overview

Pascal Corporation, founded in 1974 and based in Hyogo, Japan, is a manufacturer of automation equipment and systems. Its product range includes work clamping systems, gas springs, injection mold machines, and pallet clamps, catering to various industrial applications. Additionally, it offers die casting machines, press machines, auto couplers, and a selection of robot products, including expansion clamps, gas balancers, and tool changers. Its offerings find utility across industries, enhancing manufacturing processes, ensuring precision, and optimizing efficiency in workholding, and material handling. Since 1999, the company has maintained ISO9001 certification for its quality management system.

-

-

-

-

-

MITSUHASHI CORPORATION

Air Shaft

Company Overview

Mitsuhashi Corporation is a manufacturer and supplier of packaging devices and converting equipment established in 1944 in Kyoto, Japan. The company specializes in producing industrial machinery and equipment for paper and film packaging and conversion. These include pouch loaders, film meandering control devices, and card dispensers. The company also offers product customization as well as technical support and repair services for its clients with unique projects. It mainly serves customers in the paper, packaging, and pharmaceutical sectors.

-

-

-

-

-

SUPER TOOL co. ltd.

Burr Clamp Air Type TDBA200F / 201F

Company Overview

SUPER TOOL Co., Ltd., established in 1918 in Japan, is a manufacturer of general and specialized tools for building and bridge construction, civil engineering, shipbuilding, and similar industries. The company offers an extensive line of specialty tools used by tradespeople and skilled workers that includes ratchet wrenches, clamps, portable cranes, jig clamping tools, piping tools, and more. SUPER TOOL Co., Ltd. also offers custom tool design and production as well as custom machinery production for commercial clients.

-

-

-

-

-

DEHN SE

Clamps, Connectors

Company Overview

DEHN SE, established in 1910 and based in Neumarkt i.d.OPf., Germany, is a renowned manufacturer and supplier of devices meant for protection against lightning and surges. The company's product range includes power supply systems, IT systems, lightning protection, safety equipment, and PCB and Design-in. These offerings are pivotal for safeguarding persons, buildings, and electronic systems from potential hazards related to lightning and electrical surges. It serves industries such as Electrical, Electronics manufacturing, Railways, and Energy. The company's services include DEHN services, planning support, DEHN test centre, and maintenance tests.

-

-

Air Clamp Manufacturer Ranking

*Including some distributors, etc.Ranking as of April 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Bimba Ltd |

50.0%

|

| 2 | GOOD HAND |

50.0%

|

Derivation Method

The ranking is calculated based on the click share within the air clamp page as of April 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- Pascal Corporation.: 400

- KOSMEK LTD.: 270

- MITSUHASHI CORPORATION: 112

Newly Established Company

- KOSMEK LTD.: 1986 (38 years ago)

- Pascal Corporation.: 1974 (50 years ago)

- Carr Lane Manufacturing: 1952 (72 years ago)

Company with a History

- MITSUHASHI CORPORATION: 1944 (80 years ago)

- Carr Lane Manufacturing: 1952 (72 years ago)

- Pascal Corporation.: 1974 (50 years ago)

Air Clamp Manufacturers in United States

*Including some distributors, etc.

Global Distribution of Air Clamp Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

4 | 50.0% |

United States of America

United States of America

|

3 | 37.5% |

Germany

Germany

|

1 | 12.5% |

List of Air Clamp Products

28 products are listed.

Osaka Kakuda Kogyo Co., Ltd.

At the same time, multiple operation air clamp No.55s -106s

Last viewed: 22 hours ago

■ Characteristics ・ It is a product -made product. -The air clamps can be operated at the same time, and are used to incorporate them into automat...

Osaka Kakuda Kogyo Co., Ltd.

At the same time, multiple operation air clamp No.ac450S -650S/56s/No.100s ~ 501s

Last viewed: 21 hours ago

■ Characteristics -The air clamps can be operated at the same time, and are used to incorporate them into automated devices, and can increase their...

Osaka Kakuda Kogyo Co., Ltd.

At the same time, multiple operation air clamp No.55-106

Last viewed: 21 hours ago

■ Characteristics ・ It is a product -made product. -The air clamps can be operated at the same time, and are used to incorporate them into automat...

Osaka Kakuda Kogyo Co., Ltd.

At the same time, multiple operation Air Clamp NOAC450-650/No.56-501

Last viewed: 22 hours ago

■ Characteristics -The air clamps can be operated at the same time, and are used to incorporate them into automated devices, and can increase their...